Inventing Key Smart Factory Technologies to Accelerate Industry 4.0

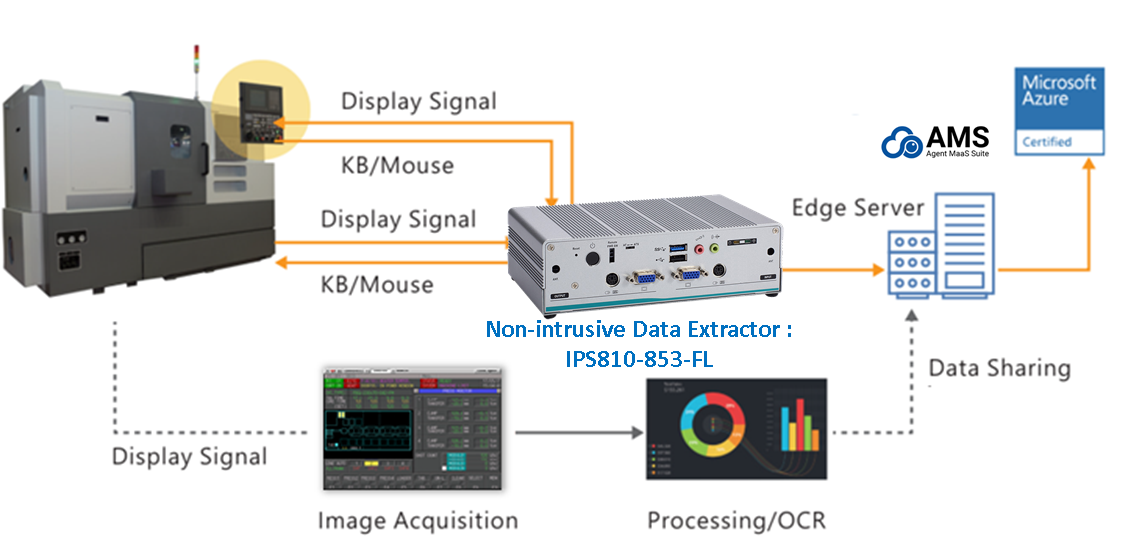

One of the biggest challenges of smart manufacturing and Industry 4.0 is the fact that more than 85 percent of existing machines are not connected to the Internet, with many of them lacking even basic capabilities. To simplify network deployment for smart factories, Axiomtek has introduced electromechanical integration and communication technologies into traditional equipment to create an automated data acquisition system. The data acquisition system will employ non-intrusive techniques to extract production data directly from old factory machines and then transform the acquired data into insightful information to be further used for optimizing operations, such as improving production efficiency and reducing manufacturing costs. By utilizing non-intrusive data extraction technology to break through the limitations of legacy equipment inaccessible via the Internet, enterprises will be able to replicate the basic structure of the "smart factory" under the current equipment and thus save construction and labor costs.

Challenges faced by users

Connecting the unconnected

• Legacy equipment doesn’t have a lot of connectivity options.

• Upgrading legacy equipment is too expensive.

• Some legacy equipment has phased out.

Data collection difficulties

• Different equipment comes with different protocol and API; the log is also all different formats.

• The integration of data occurrences difficult

AX-RCS software built-in

The IPS810-853-FL is not a pure hardware platform; the system combines AX-RCS data acquisition software as a total solution. Through the hardware and software integration, users can easy to deploy their non-intrusive data extraction solution with their corresponding legacy machines. No matter your operating systems or font formats, the AX-RCS with optical character recognition (OCR) and deep learning technologies can ensure that characters are recognized accurately. Besides, the AX-RCS provides unique functions to overcome bottlenecks from legacy machines, including multi-pages, keyboard/mouse control record and hot key setting, etc. The AX-RCS has friendly UI design that operators can change the configuration settings easy to increase the production efficiency. IT staffs also can depend on the data and log files that generate from the AX-RCS to build up their own database and create analysis report

The advantages of non-intrusive data extractor

• Improves management efficiency - Reduce operator and engineer access to the lab

• Improves the working environment - Increase the ratio of people to tools and cycle time

• Production optimization - Increases automation efficiency with less manpower

• User-friendly interface - Easy to set up and remotely operable.

• Urgent notice - Notifications of emergencies or unusual events with rapid response

• Standalone hardware - will not occupy any device resources

• Enhanced networking capabilities - Enhance network connectivity for legacy devices

IPS810-853-FL – fanless data extractor

• Using optical character recognition (OCR) to collect content of equipment

• Intel® Atom® processor N3160 quad-core onboard • Supports real-time display image via VGA input & output

• Supports PS/2 keyboard and mouse input & output control

• 2 COM, 2 GbE and 8-CH DI/DO

• 1 PCI Express Mini Card slot for WWAN or WLAN kit

• Built-in AX-RCS software

AX-RCS – specific data acquisition software

• Supports OCR and Deep Learning technology

• Detection and notification of abnormal conditions