ADLINK’s MCM-100 machine condition monitoring edge platform highlights around-the-clock continuous data collection and vibration measurement with maximized precision and sampling rates for rotating machinery and equipment. Combining data collection, vibration analysis algorithms, computation and network connection in one system, the MCM-100 enables rotating machinery, tooling, and plant and automation equipment operators to easily overcome challenges inherent in conventional equipment maintenance.

Key Features:

- Easy to set up, ready-to-go rotary machine vibration/condition monitoring Edge Platform

- Built-in 4CH, 24-bit simultaneous sampling analog inputs, up to 128kS/s

- Supports IEPE 2mA excitation current output on each analog input to drive accelerator

- Equipped with Intel® Atom™ x7-E3950 processors (Quad core)

- Extremely compact with versatile I/O support

- Optional Phoenix GM Lite machine condition monitoring software

- Optional PCB 603C01 vibration sensor accelerometer

- Optional Wi-Fi/ 4G LTE wireless kit

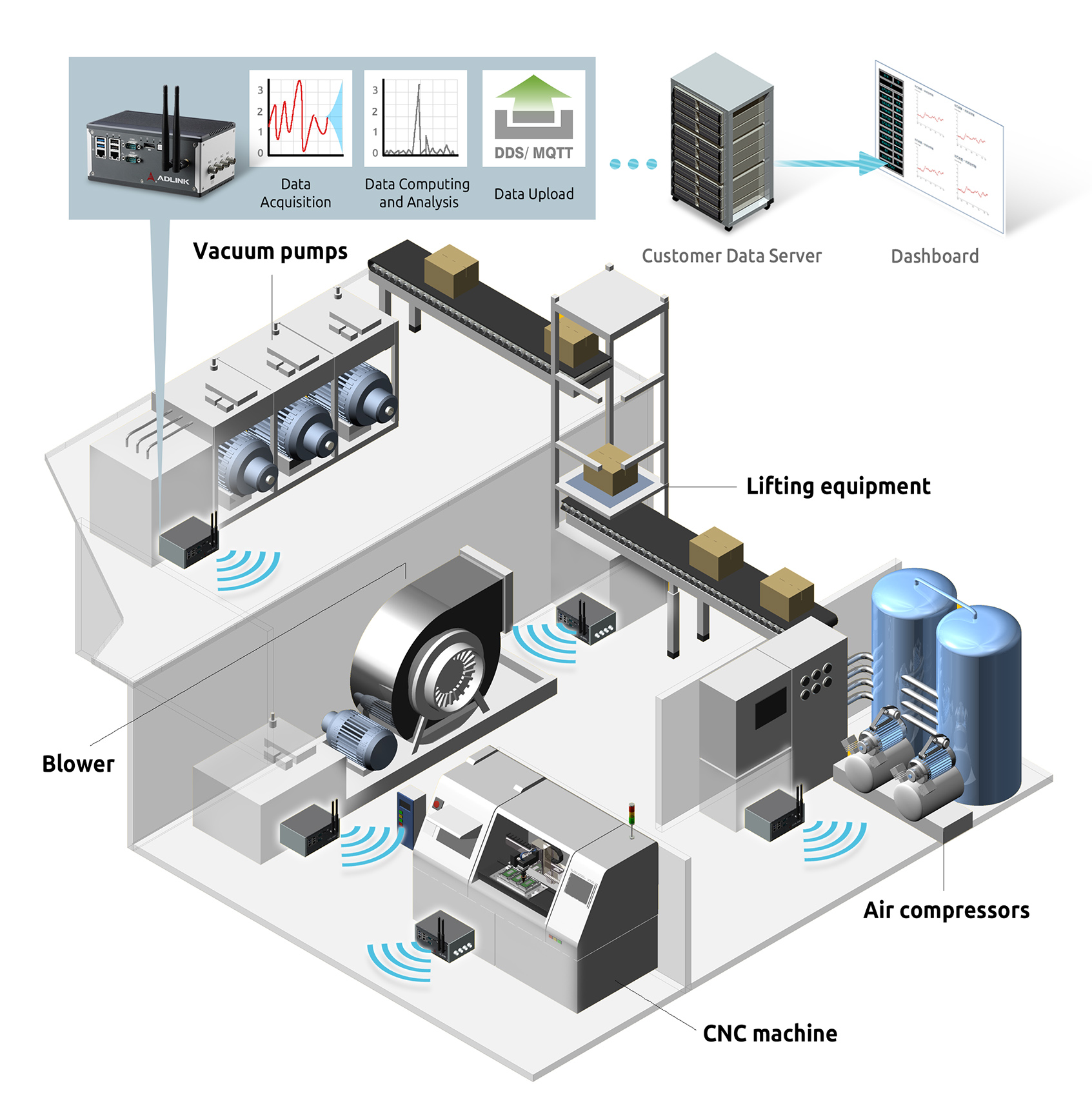

Use Case: Smart Factory Predictive Maintenance

Lifting equipment, vacuum pumps, air compressors and other rotating machines are critical in a wide variety of manufacturing and processing operations. Any suspension of production due to machine error can represent prohibitive losses in revenue.

ADLINK’s Smart equipment status monitoring solution improves dramatically on conventional manual monitoring methods, supporting 24-hour online monitoring and malfunction prediction such that precise control of equipment status can be achieved and real-time feedback maintenance provided.

Highlights:

Complete single-operation data acquisition, analysis and upload

Data acquisition, execution of domain algorithm, use of data analysis, direct conversion of machine status, use of trend analysis, warning alert and upload.

Seamless OT/IT end-to-end connection

Capable of connecting to Vortex Edge™ architecture, no programming is required to achieve fast connection with third party cloud platforms. Vortex Data Rive™ live data streaming architecture enables deployment of multiple scenes more easily.

Remote equipment overview information dashboard

Providing equipment monitoring acquiring machine information, status, and alarm information in real time, with download of historical data records and equipment maintenance information fully supported.